Supply Chain

Ferrovial fosters sustainable purchasing as part of a responsible management to favor the acquisition of products and commissioning of services that respect the environment and are rendered in socially fair conditions.

With a view to maximizing operating efficiency in supplies and services, the company builds long-term relationships with critical suppliers and calls on them to adhere to the company’s principles and policies in terms of safety and sustainability, in compliance with its Code of Business Ethics and Corporate Responsibility Policies. These engagement principles are listed in the Global Procurement Policy, whose final purpose is to provide the customer with optimum and competitive services.

PURCHASER CODE OF ETHICS

The Purchasing Divisions in Ferrovial’s different business units are governed by a single Purchaser Code of Ethics. As complementary to the Code of Business Ethics, which marks out the general lines of engagement and conduct, it applies to all staff working in the relevant Purchasing Divisions, who are provided with training and required to comply in this regard. The application of the Corporate Responsibility and Compliance Policy likewise enables a rigorous, ethical and effective management of the supply chain, thus assuring supplier commitment.

Further initiatives certifying Ferrovial’s commitment to effective and responsible supply chain management were also launched in 2016 as an extension of the use of new clauses in application of the Code of Business Ethics and Anti-Corruption Policy in orders and contracts with suppliers, Green Purchasing Catalog and a new Recycled/ Recyclable Product Supplier Study to foster their use.

Ultimately, the application of these policies and codes establishes the requirements and procedures to ensure the rapport with competent suppliers who share corporate values such as the commitment to good ethical practices and Human Rights, Health and Safety, respect for the environment and social impact.

GLOBAL PURCHASING PROCEDURE

The focus on the supply chain entails the comprehensive expense cycle, from need management to final payment. To do so, there are procedures and specific computer systems in place at each business unit to ensure the best purchasing conditions and mitigate risks through supplier selection, approval and assessment processes in line with their ability to fulfill the needs of the business. The improvements made to the computer systems reinforce the participation and competition of suppliers, transparency in the selection process and the delegation of authority for approvals.

The company has adopted a product category-based approach in each business, thus favoring knowledge of the specific purchase requirements of each one.

All contract activities are governed by clearly structured and documented procedures. General coordination in this regard is handled by the Global Procurement Committee, led by Ferrovial’s CIIO (Chief Information and Innovation Officer) and comprising the purchasing heads for each business area. In addition to capitalizing on potential synergies among areas, the committee assists in sharing good practices and improving overall purchasing activities.

In accordance with the company’s geographic diversification strategy, supply chain management is based on a Global Procurement Policy, which is applicable at the international level and establishes the basic and common principles of operation, and even specific operating procedures for each country/area where they are implemented by contemplating the local nuances of each market. This policy seeks to shore up the management adapted to the specific requirements of each project in accordance with the local supplier marketplace yet applying an international vision in relevant purchase with a view to benefiting from the extensive knowledge of the global supplier marketplace.

COMPREHENSIVE SUPPLIER MANAGEMENT

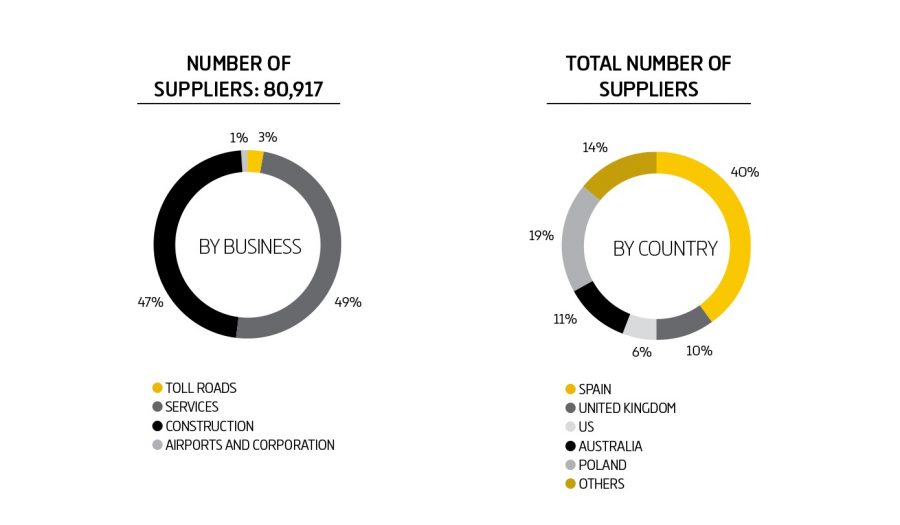

Every year Ferrovial allocates a substantial amount to suppliers and providers of goods and services that support key activities of the company. In recognition that suppliers are essential for the businesses to run properly, it is expected from them to be innovative and efficient, provide value at competitive prices, meet all the legal and functional requirements, and adhere to the required ethical practices. Suppliers and service providers are identified, assessed and commissioned, in accordance with their relevance, by their capabilities to satisfy the needs of the businesses securely, effectively and efficiently. Before the final contracting process, a selection process is conducted with an in-depth analysis of supplier suitability in terms of not only financial capacity but also environmental and social aspects. This process lets verify whether the potential supplier meets all the requested requirements. A supplier quality control and tracking system is then put into place to detect and propose measures with a view to correcting possible incidents and, in case of serious breaches of contract, taking the pertinent actions.

Of the 9,482 suppliers assessed in 2016, less than 1% were rejected. 26,801 new suppliers were incorporated during the year.

Several tools were developed in Construction and Services for the global management of suppliers, monitoring their quality and coordinating purchases. Construction has developed In-Site, a proprietary computer application implemented at the international level for easily sharing information and optimizing the processes to improve the management of construction work.

INNOVATION AND TECHNOLOGY

Innovation and technology have a critical role in yielding a synchronized supply chain with greater visibility and traceability. The use of new support technologies enables a significant increase in collaboration with the resulting improvement and transparency in information.

During 2016, the company has developed various optimization actions for different purchasing categories, prominent among which is Ferrovial Services’ OMEGA project for managing the workshops that carry out maintenance on the vehicle and machinery fleet. This project has enabled to standardize workshop processes, centralize fleet administrative management, render 100% traceability in maintenance plans and reduce costs by 10%.

A system based on electronic multimedia catalogs was launched as a cloud-based solution for sharing information with all suppliers quickly, easily and in real time. A solution for streamlining purchasing processes and assisting in decision-making, mitigating risks.

Principales categorías de producto

- Steel

- Concrete

- Bitumen

- Energy

-

Assed and/or certified suppliers

9,482

Milestones

- Green purchasing catalog initiative

- Recycled/ recyclable product supplier study

- Ferrovial services’ omega project, for managing vehicle and machinery fleet workshops

- Development of the in-site application at ferrovial agroman to optimize processes and improve construction work management

20.19 STRATEGIC CR PLAN

Reinforce ethics criteria in purchasing activities and foster the contracting of renewable energies.

GREEN PURCHASING CATA

Project conceived for shoring up acquisitions of products and services with environmental characteristics that enable a contribution to improving energy efficiency and assisting responsible decision-making for purchasing supplies and commissioning construction work and services. Some of the more prominent results entail a catalog incorporation of vehicles powered by electricity, or hybrid systems, driven by natural gas and biodiesel B30, and products manufactured with recyclable materials.